Address

- Regent Diesel

Shop No 4, Embassy Apartment,

Next to Cipla and City Center Mall,

291, Bellasis Road, Mumbai Central

Mumbai, Maharashtra 400008

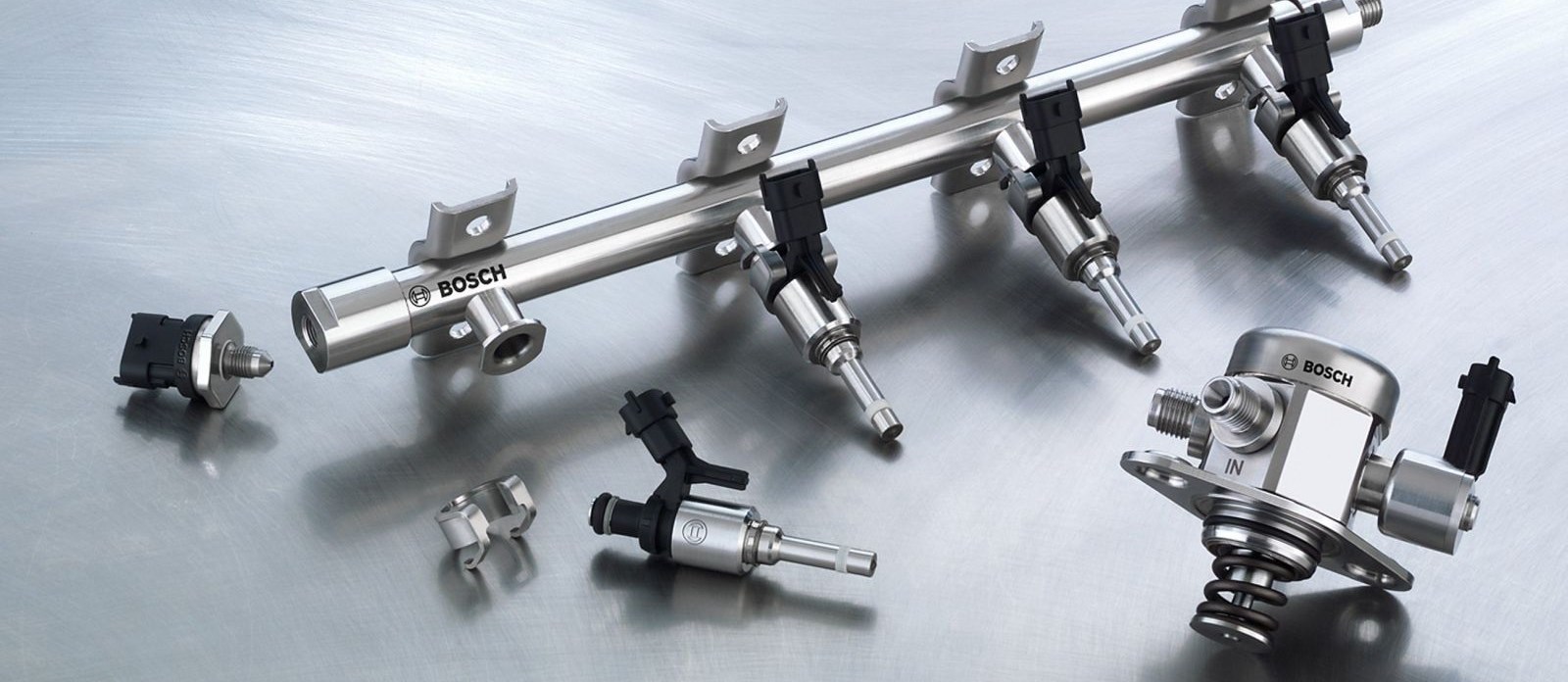

Instead of delivering the fuel via an injector in the intake track before the intake valve, GDI or gasoline direct injected engines inject a very fine mist of fuel directly in to the combustion chamber hence the name Direct Injection. Direct injectors operate at fuel pressures that vary between 450 — 3000 Psi. To achieve these pressures, the gasoline is pressurized by a high pressure fuel pump that is mechanically driven and electronically controlled.

Manufacturers preferring their own abbreviation of the system, here are some of the ones currently in use:

FSI = VW Audi ( Fuel Stratified Injection)

SCi = Ford (Smart Charge Injection)

IDE = Renault (Injection Direct Essence)

JTS = Alfa Romeo (Jet Thrust Stoichiometric)

SIDI = Holden (Spark Ignition Direct Injection)

HPI = BMW (High Precision Injection)

HPDI = Porsche (High Pressure Direct Injection)

Ecotec = GM, Vauxhall, Opel

CGI = Mercedes Benz (Charged Gasoline Injection)

DISI = Ford/Mazda (Direct-Injection-Spark-Ignition)

GDI = Mitsubishi Peugeot Citroën, Hyundai, Volvo, (Gasoline Direct Injection)

Depending on the engine requirements, this style of injectors can have varying types of spray patterns. All direct injectors will atomizing a much smaller fuel droplet size than a normal MPI injector. Conventional injector would have a fuel droplet size of +/- 165 micron, where some GDI injectors would produce a fuel droplet of only +/- 65 micron. To maintain this kind of atomization it is important to include direct injection fuel injector cleaning in your maintenance schedule.

Fuel Distribution and Atomization is equally critical to the engine’s performance, fuel economy and emission outputs. A clogged direct injector or a set of dirty direct fuel injectors will cause a range of problems and in some instances even severe engine damage.

Our testing equipment allows us to critically examine direct injectors for correct electronic operation in response to changes in mS, RPM and proper atomization as well as the proper cleaning techniques that will allow us to restore your GDI injectors to original specification.

Most direct injection fuel injectors are difficult and time consuming to remove and re-fit; would you fit a set of injectors without ensuring they are working correctly?

Insist your dealer/mechanic/technician send your dirty clogged or leaking direct fuel injectors to us for cleaning before they attempt to replace them with expensive new ones. If the injector does not perform up to spec or we can not clean them, we will not charge you for the time spent on that injector. You will only be be responsible for return shipping.

Ultrasonic fuel injector cleaning service and flow testing will restore your dirty or clogged fuel injectors to the same level of a new fuel injector.